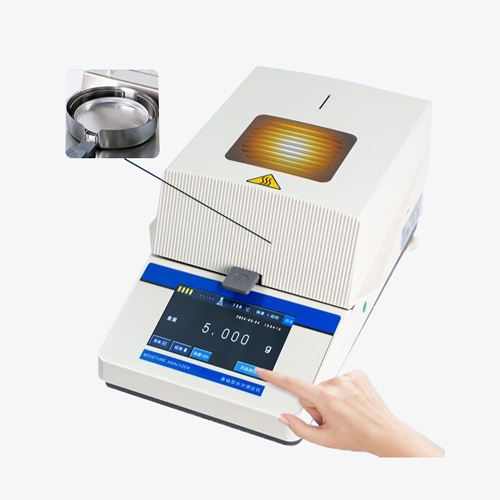

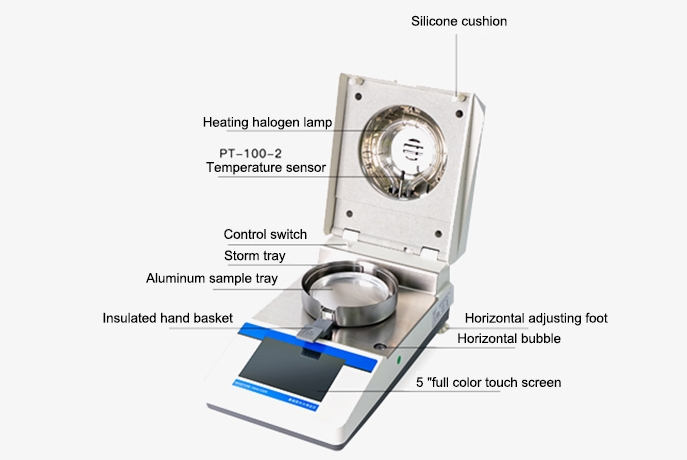

The efficient halogen moisture tester, which integrates both oven and weighing functions, is equipped with a PT-100-2 temperature sensor, a 5-inch full-color touch display, real-time dynamic curve measurement, and uses a halogen lamp as the heating source. This advanced design ensures precise and fast moisture analysis for various materials.

Simple Operation and Function Display

- Simple panel interface: Easy to use, no intervention needed, simple operation halogen rapid moisture meter.

- One-touch empty pan preheating: Simple one-touch operation, quick preheating, automatically stops after 3 minutes.

LCD Display and Analysis Functions

- High-definition intelligent touch display: Real-time dynamic analysis of curves, with direct display of moisture percentage, thousand-weight percentage, and dry weight.

- Equipped with a silicone buffer pad to prevent damage to the moisture measurement device caused by gravity when closing.

High Efficiency Connectivity and Parameter Settings

- RS232 serial port: Can be connected to devices such as printers and computers.

- Various parameter settings: Baud rate, output mode, calibration mode, test speed, stop mode, and temperature range are selectable.

Applications

SISCO's halogen moisture analyzer can be widely used in all industries requiring rapid moisture determination, such as food, pharmaceuticals, paper, chemicals, building materials, aviation, and agriculture. Its high efficiency and precision make it an ideal choice for moisture content control and quality inspection in these industries, significantly improving production efficiency and product quality.

Chemical Materials

Pharmaceutical Industry

Textile Materials

Food Industry

| Model | SISCO-MM-110 | SISCO-MM-105 | SISCO-MM-101 |

| Weighing Range | 110g | 110g | 110g |

| Weighing Accuracy | 0.01g | 0.005g | 0.001g |

| Weighing Sensor | Strain gauge/Load cell | Strain gauge HBM | |

| Moisture Test Range | 90.00%-10.00% | 95.00%-5.00% | 100.00%-0.00% |

| Moisture Readability | 0.10% | 0.05% | 0.01% |

| Dry Weight Test Range | 90.00%-10.00% | 95.00%-5.00% | 100.00%-0.00% |

| Dry Weight Readability | 0.10% | 0.05% | 0.01% |

| General characteristics | |||

| Display | 5 inch touch screen | ||

| Curve | Real time dynamic curve | ||

| Heating Source | Halogen lamp | ||

| Temperature Setting | 1°C | ||

| Temperature Range | 40℃-160℃ | ||

| Language | EN/CN | ||

| Temperature Sensor | PT-100-2 | ||

| Storage Record | 20 sets | ||

| Input Voltage | 220v 50Hz/110V 60Hz | ||

| Sample Tray Size | Φ96mm (20pcs) | ||

| Ambient Temperature | 5℃-35℃ | ||

| Test Space | 30mm | ||

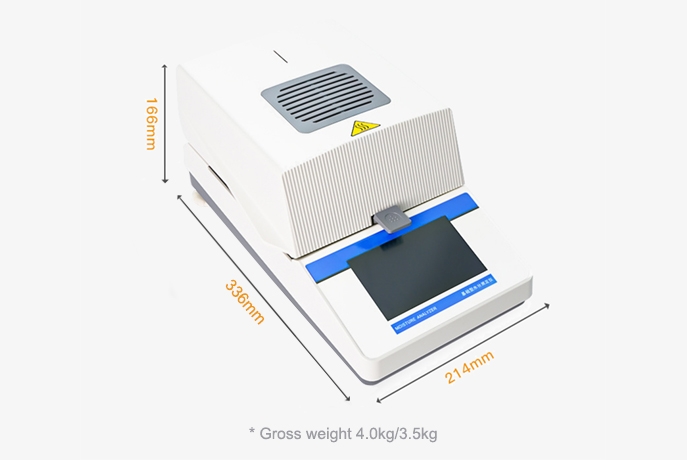

| Weight | 3.5kg | ||

Details

Dimensions (mm)

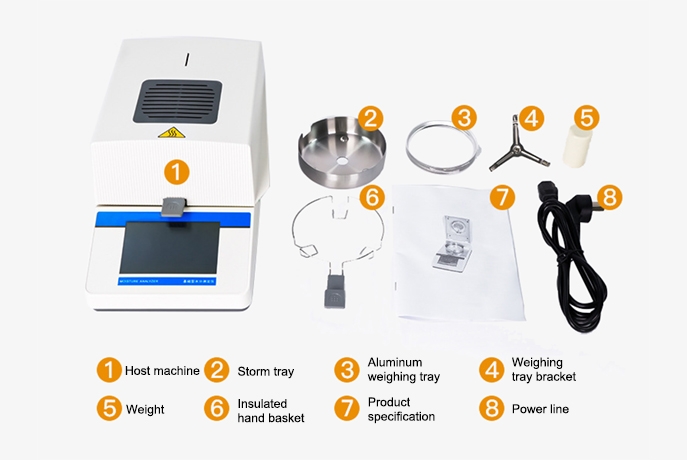

Packing List

- 1 x Moisture meter

- 1 x User Manual

- 1 x Storm tray

- 1 x Aluminum weighing tray

- 1 x Weighing tray bracket

- 1 x Weight

- 1 x Insulated hand basket

- 1 x Power line

Q1: What is a healthy moisture level?

A1: A healthy moisture level for wood typically ranges between 6% and 8% for indoor environments, such as in furniture, flooring, and other interior applications. This range helps prevent issues like warping, cracking, and mold growth. For outdoor wood or wood in more humid environments, a moisture level of up to 12% can be considered normal, though it varies depending on the specific climate and type of wood. Maintaining wood within these moisture ranges is crucial for its durability and longevity.

Q2: What factors can affect the accuracy of a humidity meter?

A2: The accuracy of a humidity meter can be influenced by several factors, including the need for regular calibration to prevent sensor drift and ensure precise readings. Temperature variations can affect humidity measurements, especially if the meter lacks temperature compensation. The quality and type of the sensor also play a crucial role, with high-quality sensors generally providing more reliable data. Environmental factors like dust and pollutants, along with improper placement near heat sources or direct sunlight, can skew results. Additionally, slow response times, power supply issues, and exposure to electromagnetic interference can all compromise accuracy. Regular maintenance, including cleaning the sensor, is essential to maintain the meter's performance.

Q3: What is the difference between a spherical induction moisture meter and a traditional pin-type moisture meter?

A3: The spherical moisture sensor differs from traditional pin-type moisture meters in several key ways. The spherical sensor is non-invasive, meaning it does not need to penetrate the material to measure moisture, thereby preventing any potential damage to the surface being tested. In contrast, pin-type moisture meters require the insertion of pins into the material, which can leave small holes or cause minor surface damage. Additionally, spherical moisture sensors typically offer a broader measurement range and deeper detection capabilities, making them ideal for assessing moisture content in a variety of materials without causing harm.

Tips: How does a ball-type moisture meter work?

A halogen rapid moisture meter that combines both oven and weighing functions works through a thermogravimetric analysis process to determine moisture content in a sample. The process begins by placing a small sample on the integrated weighing pan, where its initial weight is recorded. The sample is then subjected to heating by a halogen lamp, which provides fast and even heat to evaporate moisture from the material. As the moisture evaporates, the device continuously measures the weight loss in real-time, allowing for precise moisture content calculations. The results are displayed as moisture percentage, dry weight, or dynamic curves that track the process over time.

This type of moisture meter is highly efficient and versatile, making it useful in industries such as food, pharmaceuticals, chemicals, and agriculture. The halogen lamp speeds up the drying process compared to traditional methods, while the built-in weighing system ensures precise results. Users can adjust parameters like temperature, test speed, and stop mode to suit different types of materials. The final moisture content is displayed on a touch screen, and data can be stored or printed using an RS232 connection. This makes the halogen rapid moisture meter an ideal choice for industries needing fast, accurate moisture analysis.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.