The float flowmeter can measure liquids or gases of various viscosities and densities, has a wide flow measurement range, and can meet the flow measurement needs of different application scenarios.

Note: You can contact customer service to select a variety of models, please refer to the parameter table for details.

Applicable to Multiple Scenarios

- There are two types of float flowmeters to choose from, long tube type and short tube type. The difference is that there is no guide rod in the middle of the long tube flowmeter, and the short tube type has higher accuracy.

- The diameter below φ65 can be made into a flange connection or pipe thread connection (please consult customer service before placing an order).

Quality Assurance

- The tube body is AS, the guide rod is 304 stainless steel, the inner wall of the plastic is smooth, and it is not easy to adhere to impurities or scale. It is suitable for flow monitoring containing tiny particles or viscous media (such as sewage, or liquid medicine).

- The transparent tube body allows the float position and fluid status to be directly observed without external display. The flow value can be directly read through the scale, making it easy to quickly judge flow changes.

Application

In industrial production, a gas mass flowmeter can be used as a process automation control system detection instrument, can also be used to measure the number of materials in the total table; in energy, primary energy, secondary energy, energy-carrying masses, such as energy measurement, gas mass flowmeter is an indispensable tool in the process of energy management and economic accounting instrument. In environmental protection, gas mass flowmeter can be used for quantitative control of wastewater waste gas; in biotechnology, can be used for blood, urine, etc. detection.

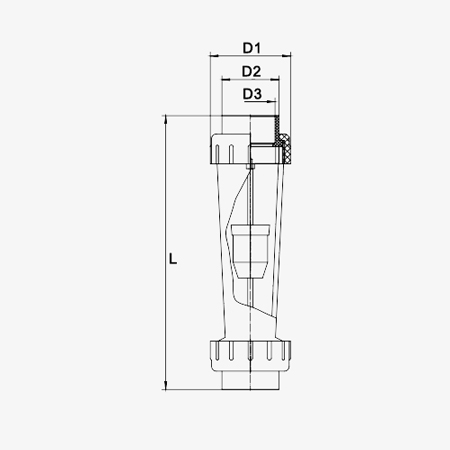

| DN | Insert Pipe (Internal Thread) Connection Size | |||||||

| Long Tube | Short Tube | |||||||

| L | D1 | D2 | D3 | L | D1 | D2 | D3 | |

| 25 | 380 | 68 | 39 | 32 | 234 | 60 | 39 | 32 |

| 32 | 375 | 74 | 50 | 40 | 288 | 74 | 50 | 40 |

| 40 | 415 | 88 | 63 | 50 | 380 | 87 | 63 | 50 |

| 50 | 435 | 98 | 73 | 63 | 348 | 98 | 73 | 63 |

| 80 | 505 | 142 | 106 | 90 | ||||

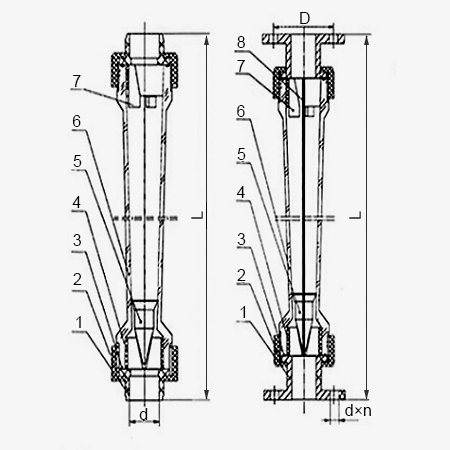

Structural Diagram

- Connecting Pipe

- Nut

- “O” Type Sealing Ring

- Lower Stopper

- Float

- Conical Tube

- Upper Stopper

- Guide Rod

Installation Dimensions

| Model | SISCO-FLOW-LZS | ||||

| DN | 25 (L/h) | 32 (m3/h) | 40 (m3/h) | 50 (m3/h) | 80 (m3/h) |

| Measuring Range | 60~600 | 0.4~4 | 0.4~4 | 0.4~4 | 5~25 |

| 100~1000 | 0.6~6 | 0.6~6 | 0.6~6 | 8~40 | |

| 160~1600 | 1~10 | 1~10 | 1~10 | 12~60 | |

| 250~2500 | 1.2~12 | 1.6~16 | 12~80 | ||

| 300~3000 | |||||

| Type | Long Tube and Short Tube | Short Tube | |||

| Accuracy | ±4% | ||||

| Temperature | 0~60℃ | ||||

| Pressure | ≤0.6MPa | ||||

Q1: Can a gas mass flow meter have perfect accuracy?

A1: In an ideal world, the flow readings from your process meter would be exactly correct, without any type of deviation. Unfortunately, this is not the case, and the errors inherent in measurement must always be identified, accounted for, and minimized as much as possible.

Q2: Does a gas mass flow meter need to be calibrated?

A2: During the production of a flow meter, several steps are required such as coil winding, lining processing, and electrode assembly. This series of operations can cause a certain amount of error and dispersion in the device, so a calibration process is required to correct the accuracy.

Q3: Do gas mass flow meters have temperature and pressure compensation?

A3: Our MF4000/5000/5700 series are all without temperature/pressure compensation. As long as the gas is under working pressure & temperature ranges, the accuracy will be as stated.

Tips: Advantages of Float Flow Meter

The structure of the float flow meter is relatively simple, without complex moving parts, so it is easy to maintain and has a low failure rate. Moreover, a float flow meter can measure a wide range of flow, which can cover different needs from small flow to large flow. Due to the characteristics of its structure and working principle, the float flow meter has good repeatability, which is conducive to ensuring the consistency of measurement. In addition, a float flow meter has a small pressure loss on the fluid, has little effect on the flow state of the fluid, and will not cause major interference to the process. Although a float flowmeter has the above advantages, when choosing a flowmeter, it should be comprehensively considered according to the specific measurement requirements and working conditions.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.