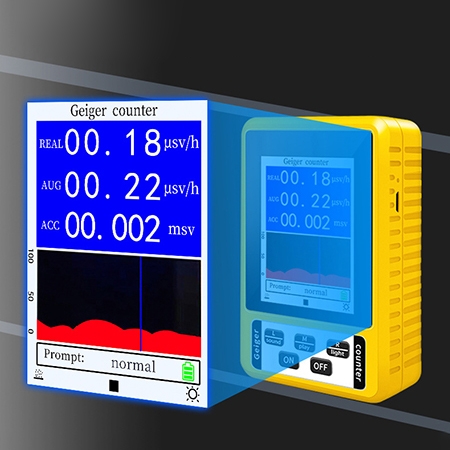

The portable radiation detector responds quickly to radiation and provides timely alerts in risky environments. The large LCD color screen of the nuclear radiation detector allows it to easily and quickly read real-time values. The small size of this nuclear radiation tester is so convenient for everyday use.

Equipped with a large 2.8” color display screen

- Automatic display of test results, no need for complex manual calculation.

- Automatically save the accumulated dose, built-in memory, and power failure can be stored for a long time.

- The detector features a large 2.8-inch color screen, providing clear and vibrant visuals for easy reading of EMF radiation levels, enhancing the overall user experience.

- The large, bright screen ensures that all readings are easily visible, even in challenging lighting conditions, allowing for quick and accurate assessments in both indoor and outdoor environments.

Adopt Geiger-Mueller counter tube, more sensitive and accurate

- The electromagnetic radiation detector is equipped with a high-performance Geiger-Müller counting tube, offering superior sensitivity for detecting even the slightest electromagnetic radiation fluctuations.

- The use of a Geiger-Müller tube ensures more accurate measurements, allowing for precise detection of radiation levels and providing users with reliable data for safety assessments.

- The Geiger-Müller tube allows for quicker detection and response to changes in EMF levels, enabling real-time monitoring with immediate feedback on radiation intensity.

Dimension

Applications

SISCO radiation detector is a device used to detect and measure ionizing radiation, such as alpha, beta, gamma rays, and neutrons. Radiation detectors are used in medical imaging, industrial safety, environmental monitoring, and security to measure ionizing radiation. They help ensure safe radiation levels, detect contamination, and prevent the unauthorized transport of radioactive materials. They’re also crucial in scientific research for studying radiation effects.

Environmental

Security

Industrial

Medical

| Model | SISCO-RD-HFS-P3 |

| Sensor Type | GM-type energy compensation tube |

| Detectable Type | β, γ, X-ray |

| Capability Range | 20 keV-3 meV≤±30%(137Cs-) |

| Sensitivity | 80 CPM/μSv/(C0-60) |

| Test Accuracy | 0.01 μsV/h |

| Implementation Range | 0-99.99 μSv/h |

| Accumulation | 0-99.999 mSv |

| Real-time Error | ≤10% |

| Average Error | ≤3% |

| Material | ABS |

| Dimensions | 106*70*30mm |

| Weight | 106g |

Detail

Q1: What is a radiation detector?

A1: A radiation detector is a device designed to detect and measure ionizing radiation, such as alpha, beta, gamma rays, and neutrons. These detectors work by sensing the interaction of radiation with matter, often producing an electrical signal that correlates with the intensity or type of radiation present. Radiation detectors come in various types, including Geiger-Müller counters, scintillation detectors, and solid-state detectors, each tailored to detect different forms of radiation or provide varying levels of sensitivity.

Q2: Do radiation detectors need calibration?

A2: Yes, radiation detectors need regular calibration to ensure accurate and reliable measurements. Calibration involves adjusting the detector to account for any changes in its performance over time, which can be caused by factors such as aging components, environmental conditions, or variations in detector sensitivity. Regular calibration helps maintain the accuracy of the readings and ensures that the detector provides precise data for assessing radiation levels. Calibration is typically performed using known radiation sources and may be required by regulatory standards to ensure compliance and safety.

Q3: Can radiation detectors detect non-ionizing radiation?

A3: Most radiation detectors are designed to detect ionizing radiation, such as alpha, beta, gamma rays, and neutrons. Non-ionizing radiation, which includes radio waves, microwaves, infrared, and visible light, requires different types of sensors. For example:

- Radio frequency (RF) meters and electromagnetic field (EMF) meters are used to measure non-ionizing radiation like radio waves and microwaves.

- Photodetectors (such as photodiodes) measure visible light, while infrared sensors detect infrared radiation.

Tips: How can a radiation detector help in a nuclear fallout situation?

In a nuclear fallout situation, a radiation detector helps by:

- Assessing Radiation Levels: Provides crucial information on the intensity of radiation in the environment.

- Guiding Safety Measures: Helps determine when it is safe to leave a shelter or take protective actions.

- Supporting Emergency Response: Assists authorities in making informed decisions about public safety and evacuation.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.