| Model | SISCO-RD-TC8500 |

| Detector | Energy-compensated GM tube |

| Detection Ray | β-rays, γ-rays, X-rays |

| Energy Range | 20kev~3.0mev≤±30%(137Cs-) |

| Flexibility | 80cpm/μSV/(Co-60) |

| Testing Accuracy | 0.01μSV/h |

| RT Measurement Range | 0.00-10mSv/h |

| Cum Measurement Range | 0.00usV/h-999.9Sv |

| RT Accuracy | ≤10% |

| Avg Accuracy | ≤3% |

| Record Groups | 1000 groups |

| Temp. Measurement Range | 20-60℃ |

| Temp. Measurement Resolution | 0.001 |

| Temp. Accuracy | ±2℃ |

| Humidity Measurement Range | 0~100% |

| Humidity Accuracy | ±3% |

| Humidity Resolution | 0.001 |

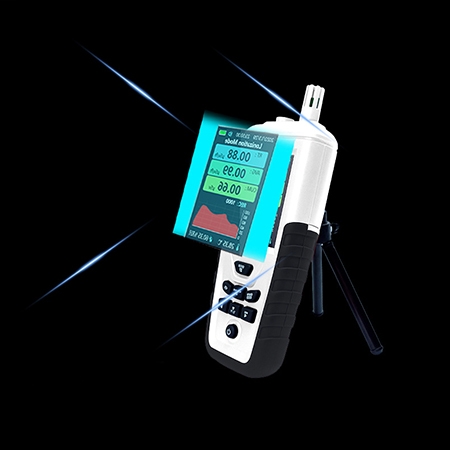

| Screen | 3.2 inch full-color screen (320*240) |

| Weight | 750g |

| Size | 222*80*46mm |

Detail

Buy a radiation meter online from SISCO. The portable radiation detector has functions of automatic data record storage and voice broadcast operating system, it will automatically record each monitoring data, and it can store 1000 groups of data, and the process of operation will be broadcast by voice.

Large LCD display for more precise readings

- The nuclear radiation detector features a generously sized screen, making it easier to view and interpret radiation levels even in low-light or high-stress environments. This improves user experience, especially in emergency situations.

- The larger display allows for more precise readings by showing data clearly and in greater detail, minimizing the risk of misinterpretation and ensuring accurate monitoring of radiation levels.

- With the increased screen size, the detector can display multiple radiation metrics simultaneously, such as dose rate, cumulative exposure, and average readings, providing a comprehensive overview in real-time.

1000 sets of data records

- The electronic radiation detector features a built-in memory capable of storing up to 1000 sets of data records, allowing for long-term monitoring and detailed analysis of radiation levels over extended periods.

- Users can track historical radiation exposure and easily review past measurements, ensuring precise and thorough radiation management for both safety and compliance purposes.

- The nuclear radiation detector with the ability to store such a large volume of data, users can retrieve and analyze radiation trends over time, which is particularly valuable in monitoring radiation fluctuations in high-risk areas or during emergency situations.

Dimension

Applications

SISCO radiation detector is a device used to detect and measure ionizing radiation, such as alpha, beta, gamma rays, and neutrons. Radiation detectors are used in medical imaging, industrial safety, environmental monitoring, and security to measure ionizing radiation. They help ensure safe radiation levels, detect contamination, and prevent the unauthorized transport of radioactive materials. They’re also crucial in scientific research for studying radiation effects.

Environmental

Security

Industrial

Medical

Q1: What is a radiation detector?

A1: A radiation detector is a device designed to detect and measure ionizing radiation, such as alpha, beta, gamma rays, and neutrons. These detectors work by sensing the interaction of radiation with matter, often producing an electrical signal that correlates with the intensity or type of radiation present. Radiation detectors come in various types, including Geiger-Müller counters, scintillation detectors, and solid-state detectors, each tailored to detect different forms of radiation or provide varying levels of sensitivity.

Q2: Do radiation detectors need calibration?

A2: Yes, radiation detectors need regular calibration to ensure accurate and reliable measurements. Calibration involves adjusting the detector to account for any changes in its performance over time, which can be caused by factors such as aging components, environmental conditions, or variations in detector sensitivity. Regular calibration helps maintain the accuracy of the readings and ensures that the detector provides precise data for assessing radiation levels. Calibration is typically performed using known radiation sources and may be required by regulatory standards to ensure compliance and safety.

Q3: Can radiation detectors detect non-ionizing radiation?

A3: Most radiation detectors are designed to detect ionizing radiation, such as alpha, beta, gamma rays, and neutrons. Non-ionizing radiation, which includes radio waves, microwaves, infrared, and visible light, requires different types of sensors. For example:

- Radio frequency (RF) meters and electromagnetic field (EMF) meters are used to measure non-ionizing radiation like radio waves and microwaves.

- Photodetectors (such as photodiodes) measure visible light, while infrared sensors detect infrared radiation.

Tips: HHow to maintain an electronic radiation dcetector?

To ensure your Electronic Radiation Detector functions properly and provides accurate readings, follow these maintenance guidelines:

- Battery Check: Regularly inspect the battery level and replace it as needed. Low power can lead to inaccurate readings or device failure.

- Clean Carefully: Wipe the exterior with a soft, damp cloth to remove dust or contaminants. Avoid using abrasive materials or harsh chemicals that may damage the device.

- Sensor Inspection: Periodically check the sensor area for any signs of damage or contamination. A damaged sensor may reduce the accuracy of the device or render it ineffective.

- Test Regularly: Perform functional tests to ensure the detector responds to radiation sources accurately. Many detectors have a self-test function that checks internal components and sensors for proper operation.

- Avoid Harsh Environments: Minimize exposure to extreme conditions like high moisture, chemicals, or mechanical shocks.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.