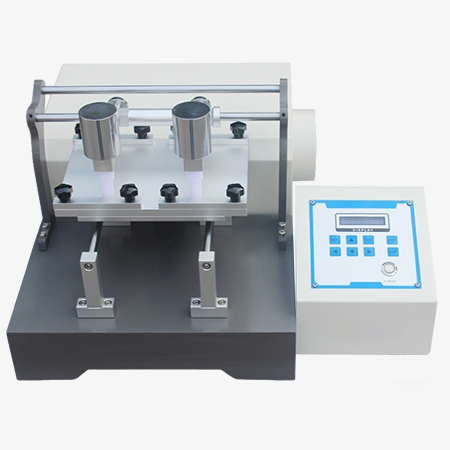

The SISCO electric rubbing color fastness tester is a precision instrument designed to determine the color fastness of textiles to rubbing (crocking). It simulates the actual wear conditions during fabric use, providing reliable and repeatable testing results. This device is widely used in quality control laboratories and textile research centers to assess the durability of dyed or printed fabrics under dry or wet rubbing conditions.

Features of an electric rubbing color fastness tester

- Automatic Operation: Electric drive ensures consistent rubbing speed and pressure, improving testing efficiency and repeatability.

- Dual Testing Modes: Supports both dry and wet rubbing tests to evaluate different usage scenarios.

- Digital Display: Intuitive interface with real-time display of test progress and cycle count.

Technical Specifications of an electric rubbing color fastness tester

- Rubbing stroke: 100mm (adjustable)

- Rubbing speed: 60 ± 5 cycles/min

- Load weight: 9N (standard), customizable

Applications

The SISCO electronic rubbing fastness tester is a professional instrument used to test the color fastness of textiles, mainly evaluating the durability of dyed fabrics under dry and wet friction conditions. This device is widely used in textile, clothing, printing and dyeing, testing institutions and research institutes, and is a standard equipment for conducting friction color fastness testing.

R&D center

R&D center

Dyeing and printing factories

Dyeing and printing factories

Quality control laboratories

Quality control laboratories

Textile and apparel industry

Textile and apparel industry

| Model | SISCO-EFT-HD5622C |

| Friction speed | 30cpm |

| Friction hammer load | 9N |

| Friction hammer size | φ16mm |

| Test piece | (22*3) cm |

| White cotton cloth | (5*5) cm |

| Machine weight | Approximately 38kg |

| Friction distance | 100mm |

| Counter | LCD 0~999,999 |

| Number of friction groups | 2 set |

| Power supply | AC220 50HZ |

| Machine size | 580 * 550 * 400 |

Q1: What is Electric Rubbing Color Fastness Tester?

A1: The Electric Rubbing Color Fastness Tester is an instrument used to test the color fastness of textiles under dry and wet friction conditions. Evaluate the degree of color transfer on the fabric surface through mechanical friction, in compliance with relevant testing standards such as ISO, AATCC, GB, etc.

Q2: What is the working principle of the electric friction color fastness tester?

A2: The device uses an electric device to drive the friction head, performs a specified number of reciprocating frictions on the surface of the sample, and then measures its color transfer through a gray card or instrument to determine its color fastness level.

Q3: What are the accessories for the Electric Rubbing Color Fastness Tester device?

A3: Common accessories include:

- Friction head (usually 9N or 10N)

- Friction cloth or standard white cotton cloth test platform

- Horizontal adjustment device, etc

Tips: How to choose the right electric rubber color fastness tester?

- Know your testing standards: First, check which standards you need to comply with, such as ISO 105, ASTM D2244, or industry-specific ones (e.g., automotive, footwear, industrial rubber).

- Identify what you need to test: Some testers are designed just for light/color fading under UV or Xenon lamps, others simulate wear, friction, or washing.

- Decide on the testing method: Make sure you pick a tester suitable for your method.

- Key features to look for: Some newer models have built-in digital recording or can export data to a computer.

- Machine build quality: Look for durable build (especially corrosion-resistant materials if you're working with wet tests).

- Budget: High-end models offer automation, multi-testing options, and better precision but are more expensive.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.