The drop weight test machine can accurately control the weight and drop height of the heavy hammer. It has a simple structure, easy operation, safety and reliability, and is suitable for tests in laboratories and construction sites.

Choose the Test Height and Impact Head as Needed

- There are three optional heights of 50cm/100cm/120cm, which are suitable for 1000g drop weight/8mm impact head/16mm impact head, and various tests can be performed.

- The drop impact test machine base includes a horizontal support. When the weight falls, it will hit the punch below. The size of the punch corresponds to the ground mouth of the base, which can prevent the test plate from receiving shear force at the inner edge of the last seat and thus affecting the test results.

Quality Craftsmanship Protection Test Safety

- The easy-to-operate height controller is matched with a durable impact head, reflecting the quality details.

- The weight falls through a hollow tube, and there are standard scale numbers next to the slot. The scale is clear and easy to read, and accurate measurements can be obtained.

Applications

Impact testers are widely used to study the impact toughness and brittle transition temperature of new materials, provide a basis for the selection and application of materials, and ensure that products can withstand certain impact loads during use. In the automotive industry, impact testers can test the impact performance of various mechanical parts and components, such as gears, bearings, shaft parts, etc., to ensure that they can withstand impact loads without failure in actual use. Plastic films, composite films, cartons, and plastic containers can be tested for their impact resistance through impact tests to determine their ability to protect products from impact damage during the packaging process. Impact tests are performed on sports equipment such as rackets, bats, helmets, etc., to evaluate their ability to protect athletes and their performance during use.

Material Science

Packaging Industry

Sports Equipment

Automotive Industry

| Model | SISCO-IT-QCJ50 | SISCO-IT-QCJ100 | SISCO-IT-QCJ120 |

| Material | Steel | ||

| Weight of Hammer | 1000g±19g | ||

| Diameter of Punch | 8mm, 16mm | ||

| Maximum Impact Height | 50cm | 100cm | 120cm |

| Scale Value | 1cm | ||

| Pcakaging Dimensions | 24cm×24cm×148cm | ||

| Weight | 12kg | ||

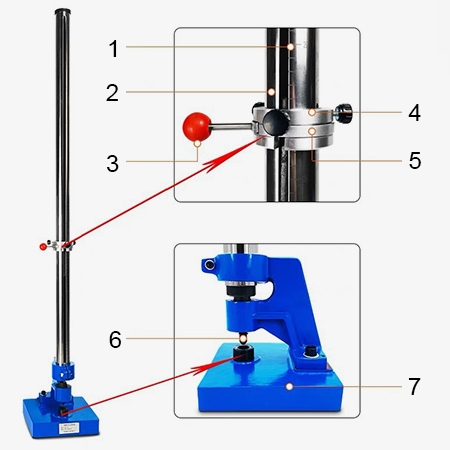

Structure Diagram

- Scale

- Slide

- Weight Handle

- Positioning Mark

- Control Pin

- Punch

- Base

Q1: What is a Charpy Impact Tester?

A1: A Charpy impact tester is a device specifically used for Charpy impact tests. It is mainly used to evaluate the toughness and fracture characteristics of metal materials under dynamic loads, especially in evaluating the low-temperature toughness of steel materials and the quality of welded joints. The working principle is mainly based on the law of conservation of energy and the energy change of an object when it is impacted instantly.

Q2: What is an Izod Impact Tester?

A2: An Izod impact tester is a device used to perform an Izod impact test, which is used to evaluate the impact toughness of plastics, polymers, glass, and other non-metallic materials. The Izod impact test is similar to the Charpy impact test, but the placement and impact method of the specimen are different. A specimen with a specified shape, size,e and notch type is clamped at one end, and the other end is used as a free end. Then, a pendulum of a specified height is used to hit the free end of the specimen once, and the work absorbed by the specimen when it breaks under impact is measured.

Q3: How to Use an Impact Tester?

A3: First, prepare the machine to ensure that the machine is in good working condition and check whether all parts are intact, including the pendulum, specimen fixture, measuring device, etc. Install the specimen correctly in the fixture of the tester. For the Charpy test, the specimen is usually placed horizontally; for the Izod test, the specimen is placed vertically with the notch facing the impact direction of the pendulum. Set the initial height of the pendulum according to the test standard to ensure that the pendulum has enough energy for the test when it is released. Release the pendulum and let it fall freely and hit the specimen. After the pendulum hits the specimen, record the final position of the pendulum or record the data through the automatic measurement system of the testing machine. Please note that different types of impact testers and different test standards may require specific operating steps and parameter settings. Therefore, before using the impact tester, the operating manual and relevant test standards provided by the manufacturer should be read and followed in detail.

Tips: How to Ensure the Safety of an Impact Test?

It is very important to ensure the safety of the impact test. Before the test, conduct a comprehensive inspection of the impact tester to ensure that the equipment is in good condition and all connections are not loose or damaged. Operators should be professionally trained, wear appropriate personal protective equipment, and be familiar with the operating procedures and safety precautions of the equipment. Ensure that all operators, recorders, and viewers stand outside the safety cordon. Properly handle the samples after the test to avoid harm to personnel and the environment. Develop and be familiar with emergency response procedures to deal with possible unexpected situations.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.