The high-quality refrigerant weight scale has a clear, easy-to-use LCD display panel and an auto shut-off function. The refrigerant scale is made with durable materials that are built to last and withstand heavy-duty use. SISCO electronic refrigerant charging scale has four models that offer different weight capacities to suit your specific needs.

Design with digital display, accurate and clear

- The digital refrigerant charging scale features a clear and accurate digital display that shows refrigerant weight with a high precision of 0.05%, ensuring exact measurements during charging and recovery.

- The display is designed to be easy to read, even in low-light conditions, with a backlight feature that enhances visibility and clarity.

- The refrigerant weight scale typically offers the ability to switch between different units of measurement of pounds, kilograms, and ounces, for versatility and convenience in various applications.

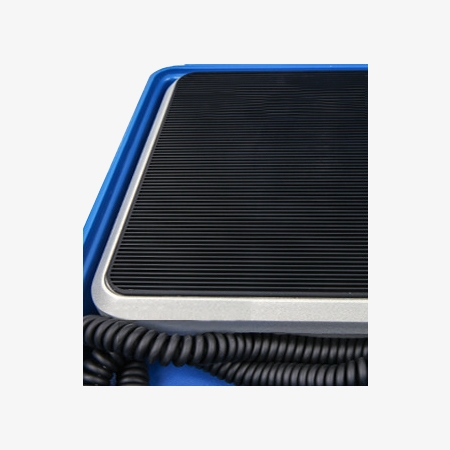

Anti-collision and anti-slip design

- The refrigerant charging scale is built with reinforced edges or protective bumpers to prevent damage from accidental drops or impacts, ensuring durability even in harsh work environments.

- Equipped with non-slip rubber feet or a textured surface, the scale stays securely in place during use, preventing any sliding or shifting while handling refrigerant cylinders.

- The rugged housing of the scale is designed to absorb shocks, protecting sensitive internal components from mechanical damage during transport or rough handling.

Applications

SISCO refrigerant scale is essential in industries like HVAC, refrigeration, automotive, pharmaceuticals, food and beverage, cold chain logistics, and manufacturing. It ensures accurate refrigerant charging and recovery, maintains system efficiency, and supports compliance with environmental regulations, preventing spoilage and energy waste in temperature-sensitive applications.

Automotive Industry

Refrigerant Industry

Food Industry

HVAC System

| Model | SISCO-ERS-50A | SISCO-ERS-50B | SISCO-ERS-100A | SISCO-ERS-100B |

| Filling Method | Manual | Automatic | Manual | Automatic |

| Maximum Range | 50kg | 100kg | ||

| Resolution | 2g | 5g | ||

| Air Port Thread | / | 1/4" SAE | / | 1/4" SAE |

| Accuracy | 0.05% | |||

| Power Supply | 9V | |||

| Dimensions | 440*340*110mm | |||

| Weight | 5kg | 6.5kg | 5kg | 6.5kg |

Q1: What is a refrigerant scale?

A1: A refrigerant scale is a specialized scale used to measure the weight of refrigerants (such as Freon or other cooling agents) being added to or recovered from HVAC/R systems. These scales are crucial for maintaining the correct charge of refrigerant in air conditioning, refrigeration, and heat pump systems.

Q2: Why is it important to use a refrigerant scale?

A2: Using a refrigerant scale ensures accurate charging and recovery of refrigerant, which helps:

- Prevent overcharging or undercharging systems.

- Maintain system efficiency and performance.

- Comply with environmental and safety regulations for refrigerant handling.

Q3: How does a refrigerant scale work?

A3: A refrigerant scale is a specialized electronic scale used to measure the weight of refrigerant, commonly used in the maintenance and charging of HVAC and refrigeration systems. It works by placing the refrigerant cylinder on a platform, where a load cell sensor accurately measures the weight and displays it in real-time on a digital screen. Technicians monitor the weight to ensure the correct amount of refrigerant is added or removed from the system, preventing issues like overcharging or undercharging that can affect system performance. Many advanced refrigerant scales feature functions such as auto-zero, overload protection, low battery alerts, and some even offer Bluetooth or Wi-Fi connectivity for remote monitoring and data logging.

Tips: How to maintain the digital refrigerant charging scale?

To maintain your digital refrigerant charging scale, follow these simple steps:

- Clean Regularly: Wipe the scale after each use to remove dirt, oil, or refrigerant residue. Clean the platform to prevent debris buildup.

- Check Batteries: Replace or recharge batteries as needed, ensuring the scale has enough power for accurate readings.

- Calibrate: Calibrate the scale every 3-6 months or whenever accuracy is in question.

- Store Properly: Keep the scale in a dry, cool place, away from extreme temperatures or moisture. Use a protective case if needed.

- Inspect for Damage: Regularly check the load cell and ensure the scale isn’t overloaded.

- Avoid Physical Damage: Keep the scale on flat surfaces and avoid dropping it to prevent damage.

By following these steps, you’ll ensure your scale stays accurate and functional for longer.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.