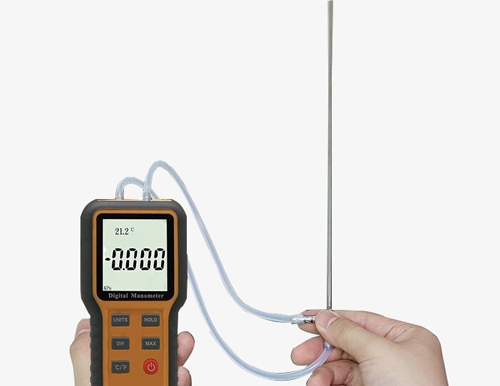

The ±89.6 kPA digital differential pressure manometer, with a rapid 0.5-second response time with a simple hose connection device, suitable for measurements and on-site calibration in HVAC systems, clean rooms, or troubleshooting any gas pressure systems.

High-Efficiency Recording

- Zeroing function: ensures more precise and reliable pressure measurements.

- Recording mode: continuous monitoring assistant, capable of recording pressure values over a period of time.

- Differential mode: capable of measure and display the difference between two different pressures.

- LCD backlight display: High-quality HD display with backlight for easy operation.

Professional High-Quality Sensor

- Range up to 89.6 kPA, resolution 0.01, fast and sensitive, and precise measurement.

- Stores pressure values in the differential pressure manometer, capable of storing up to 100 sets.

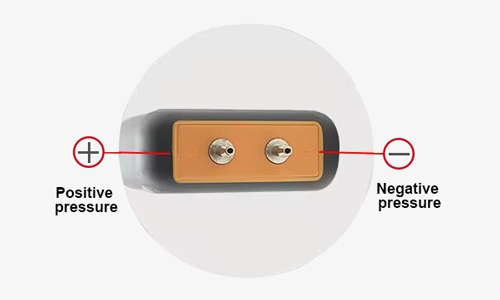

- Sensor probe has +(positive) / -(negative) levels, capable of measuring differential pressure, positive pressure, and negative pressure.

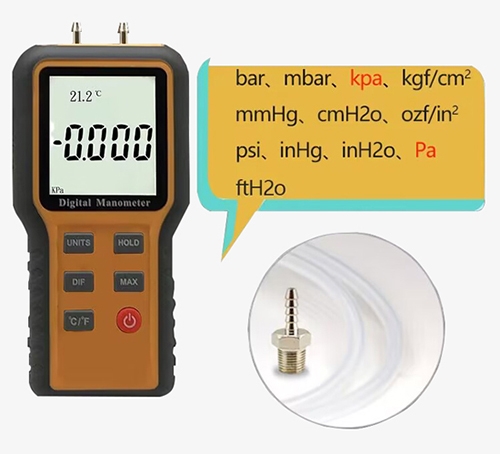

12 Pressure Unit Conversions

- Anti-slip edge design, makes the manometer not easy to slip.

- Achieve direct data output without the need for further conversion.

- Flexible choose Psi, kgf/cm², ozf/in², bar, mbar, kPa, Pa, inHg, mmHg, inH2O, ftH2O, cmH2O.

Applications

SISCO differential pressure manometer tester is widely used for measuring pressure in fans and blowers, pipeline, air conditioning and ventilation systems, air velocity, furnace pressure, orifice differential pressure, etc. Also utilized for air-fuel ratio control and automatic valve control during combustion processes, as well as for monitoring blood pressure and respiratory pressure in healthcare equipment.

Air Conditioner

Orifice

Pipeline

Blower Equipment

| Model | SISCO-DPM-M1208 |

| Max Pressure | 89 kPA |

| Data Storage | 100 sets |

| Measurement Range | ± 89.6 kPa = ± 12.999 PSI |

| Accuracy | ± 0.3% FSO ( 25°C) |

| Measurement Rate | 0.5 seconds |

| Room Temperature Measurement | ℃/°F |

| Low Battery Indicator | ≤ 6.8V display |

| Repeatability | ± 0.2% (Max+/-0.5 FSO) |

| Auto Shut-off Approximately | 15 minutes of inactivity |

| Display for Exceeding Positive Pressure Range | Err0 |

| Display for Exceeding Negative Pressure Range | Err1 |

| Operation Temperature | 0~50°C, 0-50℃ (32-122°F) |

| Storage Temperature | -10~60°C, (14-140°F) |

| Working Power | 9V |

| Net Weight | 200g |

Range and Resolution

| Unit | Range | Resolution |

| kPa | ± 89.6 | 0.001 |

| psi | ± 12.999 | 0.001 |

| kg/cm² | ± 0.909 | 0.001 |

| oz/in² | ± 207.8 | 0.01 |

| Bar | ± 1.16 | 0.001 |

| mbar | ± 896.0 | 0.1 |

| inHg | ± 26.44 | 0.001 |

| mmHg | ± 671.5 | 0.1 |

| inH2O | ± 359.8 | 0.01 |

| ftH2O | ± 29.95 | 0.001 |

| cmH2O | ± 913.1 | 0.1 |

| Pa | ± 89600 | 1 |

Details

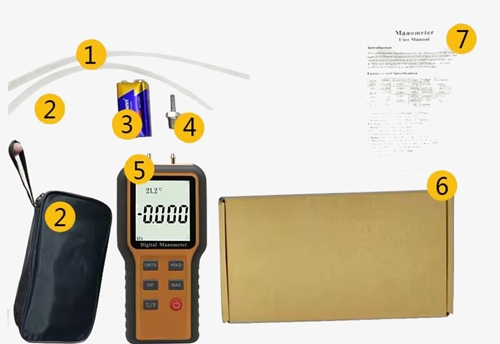

Packing List

- 1 x Manometer

- 1 x Box

- 1 x Specification

- 1 x Protective case

- 1 x USB cable

- 1 x Battery

- 2 x Soft tube

- 1 x Hardware fittings

Q1: What is the function of digital differential pressure manometer?

A1: The function of a digital differential pressure manometer is to measure the pressure of a fluid, typically in a closed system. It can be used to monitor and control pressure levels in various applications, such as in industrial processes, HVAC systems, and medical equipment. Manometers are designed to provide accurate and precise pressure readings, allowing for proper maintenance and troubleshooting of systems.

Q2: What is the sensitivity of a digital pressure manometer?

A2: The sensitivity of a digital pressure manometer refers to its ability to detect small changes in pressure. It's typically measured in terms of the amount of deflection or movement of the manometer fluid (e.g., liquid column) in response to a change in pressure.

A highly sensitive manometer will show noticeable deflection even with small changes in pressure, while a less sensitive one will require larger pressure changes to produce the same deflection. Sensitivity is influenced by factors such as the diameter of the tubing, the density of the manometer fluid, and the scale markings on the manometer.

Q3: Why is mercury used in a manometer instead of water?

A3: Mercury is used in manometers instead of water due to its higher density, which allows for more accurate measurements of higher pressures. Additionally, mercury's incompressibility and temperature stability make it suitable for various environmental conditions. However, mercury's toxicity has led to increasing concerns, prompting the exploration of alternative fluids in manometers, especially in applications prioritizing safety and environmental protection.

Tips: How does a manometer work?

The working principle of a manometer is based on the displacement of a liquid when subjected to pressure. Typically consisting of a sealed U-shaped or straight tube filled with liquid (such as water or mercury), a manometer operates by measuring the displacement of the liquid column in response to the applied pressure.

The magnitude of the pressure is determined by measuring the height difference of the liquid column. Usually, a reference point (such as atmospheric pressure) is used as the zero point of pressure, and the change in height of the liquid column under the applied pressure relative to this reference point is measured.

Specifically, when the pressure being measured is applied to one side of the manometer, the liquid in the tube moves, causing the liquid level on that side to rise while the level on the other side falls. By measuring the difference in height between the two liquid levels, the pressure can be determined.

The working principle of a manometer may vary depending on its type and application, but the basic principle involves using the displacement of a liquid under pressure to measure pressure.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.