The digital electrical conductivity meter can measure resistivity, TDS, salinity, and humidity, supports 1000 sets of data storage, connects to an RS232 serial printer through a matching printing line, and has a USB interface with special communication software to realize data transmission.

Complete Functions

- Conductivity measurement instruments can detect conductivity, resistivity, TDS, reading, and temperature. It belongs to the 1.0 level instrument.

- Intelligently judge the endpoint and support multiple reading methods and reading times.

- Automatically identify GB standard conductivity solution, 4 GB standard solutions are defaulted, and support 1-3 point conductivity electrode calibration.

- Automatic/manual temperature compensation can be used, and the temperature unit can be selected in ℃ and ℉.

Easy to Operate

- Powered by a rechargeable large-capacity lithium battery, supporting connection to PC and mobile power supply for charging.

- Adopting high-definition color LCD touch screen, clear display, adjustable backlight, navigation operation interface, and sliding operation.

- With multiple viewing methods, the viewing results can be displayed in curve form.

- With a protective cover and wrist strap, it can be used to prevent falling in daily use.

Applications

sisco conductivity meter, an intelligent online chemical analyzer, is widely applied for continuous monitoring and measurement of EC value or TDS value or ER value and temperature in the solution in the industry of thermal power, chemical fertilizer, environmental protection, metallurgy, pharmacy, biochemistry, food and water, etc.

| Model | SISCO-CDTYM-1VTC | |

| Conductivity | Range | 0.000μS/cm~1000mS/cm |

| Minimum Resolution | 0.001μS/cm | |

| Electronic Unit Reference Error | ±1.0%FS | |

| Resistivity | Range | 5.00Ω·cm~20.00 MΩcm |

| Minimum Resolution | 0.01Ω·cm | |

| Electronic Unit Reference Error | ±1.0%FS | |

| TDS | Range | 0.000mg/L~300g/L |

| Minimum Resolution | 0.001mg/L | |

| Electronic Unit Reference Error | ±1.0%FS | |

| Salinity | Range | (0.00~8.00)% |

| Minimum Resolution | 0.01% | |

| Electronic Unit Reference Error | ±0.2% | |

| Temperature | Range | (-5.0~110.0)℃/(23.0~230.0)℉ |

| Minimum Resolution | 0.1℃/0.1℉ | |

| Electronic Unit Indication Error | ±0.2℃ | |

| Power Adapter | Input | AC 100~240v |

| Output | DC 5V | |

| Dimension | 90mm×255mm×40mm | |

| Weight | 0.5kg | |

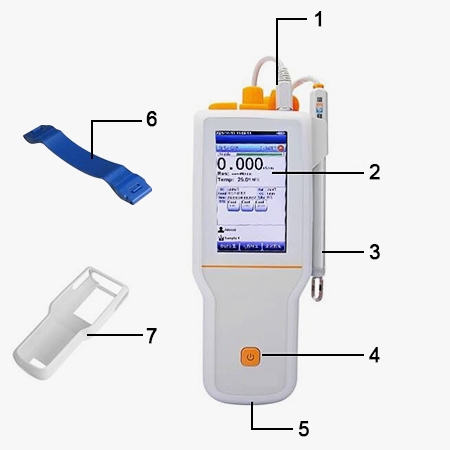

Structure Diagram

- Waterproof Silicone

- LCD Screen

- Electrode

- Button

- MICRO USB

- Wrist Strap

- Protective Case

Q1: What is a conductivity meter?

The conductivity meter is mainly an instrument for measuring the current capacity of the liquid medium. They are generally used for continuous monitoring of conductivity values in electric power, the chemical industry, metallurgy, environmental protection, pharmaceuticals, fields, lakes, scientific research, food and tap water, as well as in water treatment and aquaculture experiments.

Q2: How does a conductivity meter work?

Conductivity Meter Principle Conductivity is a numerical representation of the ability of a solution to conduct electrical current. The conductivity of water has a certain relationship with the number of inorganic acids, alkalis and salts contained in the water. When their concentrations are low, the conductivity increases with the increase of the concentration. Therefore, this indicator is often used to infer the total concentration or salinity of ions in water. Conductance (G) is the inverse of resistance (R). As a result, when two electrodes (usually platinum or platinum black) are inserted into the solution, the resistance R between the two electrodes can be measured. According to Ohm's law, the resistance value is proportional to the electrode spacing L (cm) and inversely proportional to the electrode's cross-sectional area a (cm2 ).

Q3: What is a conductivity meter used for?

- Water quality monitoring: The conductivity is affected by salt, inorganic acid, alkali, etc. in the water, so the higher the conductivity, the higher the concentration in the water will be reflected, the total concentration and salt content of ions in the water can be understood, and the purity of the water quality and due to the control of the production process, the conductivity of the water will vary with the TDS content in the water.

- Electroplating solution: Conductivity is an important parameter reflecting the electroplating solution. It can reduce the voltage in the electroplating bath and improve the dispersion ability of the electroplating solution. The conductivity of the electroplating solution can be reflected by measuring the conductivity.

- Atmospheric monitoring: The conductivity meter is used in atmospheric monitoring mainly for pollutants contained in the atmosphere such as carbon monoxide, sulfur dioxide, carbon dioxide and various nitrogen oxides. It can pass the gas absorption device and pass the gas through the absorption liquid to check the change of conductivity and monitor exceeding the standard in the polluted area

Tips: Cleaning and Maintenance of The Conductivity Meter

In order to ensure the accuracy and stability of the conductivity meter, it mainly includes cleaning and calibration of the electrode and maintenance of the instrument casing. The electrode is a very important component of the conductivity meter, and its cleanliness directly affects the accuracy of the measurement results. The specific steps include regularly checking whether the electrode has contaminants attached, rinsing with clean water, and focusing on cleaning the sensitive parts of the electrode. Use a soft cloth or paper towel to gently wipe the electrode surface, and never use hard objects to wipe the electrode to avoid damaging the electrode surface. If there is difficult-to-remove dirt on the electrode surface, use an appropriate amount of neutral detergent to gently wipe it, and then rinse it with clean water. For electrodes that are not used for a long time, they should be soaked in distilled water to keep them moist. And calibrate the electrode regularly to ensure its measurement accuracy.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.