A thermal imaging camera is a device that uses infrared thermal imaging technology to convert the temperature distribution of a target object into a visible image. The infrared radiation emitted by the surface of an object is passively received and measured by infrared sensors and visible light cameras, and images are generated by means of signal processing, photoelectric conversion, etc. The infrared sensor is responsible for receiving and measuring infrared radiation, while the visible light camera provides additional visual information, which together provide a more comprehensive observation experience. These images can show the temperature distribution on the surface of the object, and different colors or brightness correspond to different temperature areas.

Thermal imaging cameras use infrared thermal imaging technology to form thermal images. Its application scenarios are very wide. In this article, we will introduce you to some of the main application areas. For more test and measurement tools, please visit the SISCO online store.

In the field of security monitoring, infrared thermal cameras do not require any lighting, and can clearly image by relying on the infrared heat energy radiated by the object itself, which can truly achieve 24-hour monitoring. In severe weather conditions such as rain, fog, and snow, the target can still be observed normally, and personnel, vehicles, etc. can be effectively monitored. This is because the thermal imaging device passively receives the thermal radiation of the target itself. The temperature and infrared radiation of the human body and vehicle are generally much greater than the temperature and infrared radiation of grass and trees. Therefore, it is not easy to camouflage, and can easily penetrate obstacles such as leaves and grass to accurately identify camouflaged and hidden targets.

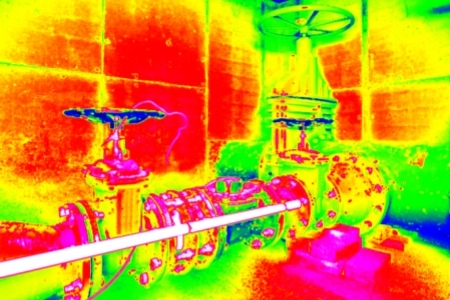

In the field of industrial detection, when electronic devices such as motors and transistors fail, they are often accompanied by abnormal temperature increases. Thermal imaging cameras can quickly diagnose faults and can also be used to monitor the temperature of electrical equipment such as generators and transformers to promptly discover hidden equipment failures and ensure production safety. In addition, in industries such as steel, petrochemicals, etc., infrared imaging cameras can be used to detect information such as corrosion, rupture, thinning, blockage, and leakage of product transmission and pipelines, refractory and insulation materials, and various reactors. It can quickly and accurately obtain the two-dimensional temperature distribution of equipment and material surfaces to ensure the smooth progress of the production process.

In the medical field, the human body itself is an infrared radiation source. When the human body develops a disease, the body's thermal balance will be destroyed. Thermal imaging cameras can accurately display and record the temperature distribution of the human body for further pathological analysis. They can be used to diagnose superficial tumors, vascular diseases, and skin diseases. During the epidemic, thermal imaging cameras can quickly screen people with abnormal body temperature and improve detection efficiency. They can also be used for temperature monitoring in crowded places such as hospitals, schools, and airports.

In the field of construction, thermal imaging cameras can detect the thermal insulation performance of buildings, find temperature differences on the surface of buildings, and help find areas with poor insulation so that measures can be taken to improve the energy efficiency of buildings. In addition, thermal imaging cameras can detect temperature changes inside buildings, thereby finding leaks and repairing them in time to avoid losses caused by leaks.

From a technical perspective, heat imaging cameras are undergoing continuous innovation. With the continuous development of infrared detection technology, the resolution and sensitivity of thermographic imaging cameras are constantly improving, enabling them to capture more subtle temperature changes. At the same time, with the widespread use of non-cooled infrared detectors, the cost of thermal temperature cameras is gradually decreasing, which has promoted their application in more fields. The most commonly used thermal imaging scanners are fixed thermal imaging cameras and portable thermal imaging cameras. The main differences between them are usage scenarios, measurement accuracy and stability, size and portability, and power requirements.

Use scenarios

Fixed thermal imaging cameras are large in size and inconvenient to carry. They need to be fixed and installed, and they may need a power supply to work. They are more suitable for long-term fixed-point detection in field operations and harsh environmental conditions. It can be fixed around the target to achieve all-round and all-weather online monitoring and can be unmanned 24 hours a day without manpower. Portable thermal imaging cameras are small in size and light in weight. They can be directly handheld and usually equipped with batteries for easy carrying. More flexible, users can move as needed, suitable for outdoor operations, such as outdoor exploration, hunting, search and rescue, etc. It is easy to carry and convenient to monitor the temperature changes in the workplace anytime and anywhere. It is mostly used for inspections and can handle abnormal situations in time.

Functional features

Fixed thermal imaging cameras have high measurement accuracy, good stability, and long service life, which can avoid errors and damage to the machine caused by human factors. They usually have more advanced functions, such as higher resolution, longer detection distances, and more complex image processing capabilities. Portable thermal imaging cameras are easier to use. Due to factors such as detection accuracy and battery power supply capacity, they may not perform as well as fixed cameras in some high-precision measurement occasions.

Image Quality

On the one hand, fixed thermal cameras usually have higher resolutions, which means they can provide clearer images and finer details. For example, some high-end fixed thermal cameras may have a resolution of 3.1 megapixels. Portable thermal cameras, especially those used as thermal imaging accessories for mobile phones, usually have lower resolutions and may not perform as well as fixed cameras in capturing fine details, but portable thermal cameras usually have a more flexible field of view angles, suitable for quick adjustment in different environments, but their refresh rate may be lower, resulting in a sluggish image. Fixed thermal cameras usually have a more fixed field of view angle, but a higher refresh rate, which can provide smoother images.