The height gauge with a dial indicator is made of cemented carbide and can measure objects of various shapes and sizes. It is suitable for a variety of occasions, such as machining, mold manufacturing, architectural design, etc.

Accurate Measurement

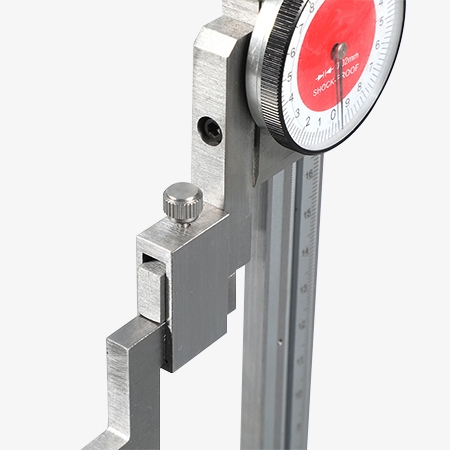

- With a micro-motion device and a streamlined base, it is easier to measure.

- Dial scale 0.02mm. Digital direct reading, clear and convenient.

- Metal limit device with fastening screws, stable and accurate reading, equipped with metric and inch quick conversion, zero setting at any position.

Quality Assurance

- The main scale line surface is laser engraved, and the scale is clear and delicate.

- The carbide measuring claws are made of high-temperature quenching technology to provide stronger wear resistance.

- Packaged in plastic boxes, it has the effect of being shockproof and anti-fall and is also convenient for storage.

Applications

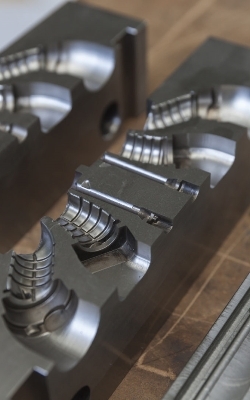

Height gauges are a precision measuring tool widely used in many fields. In the field of industrial manufacturing, height gauges are an indispensable measuring tool. It can be used to measure the size of parts to ensure that the quality of the product meets the requirements. In the field of automobile maintenance, height gauges are used to measure whether the size of automobile parts meets the standard specifications. By regularly measuring the size changes of key parts, the wear and tear of the parts can be determined and repaired or replaced in time. When installing some precision parts, height gauges are used to ensure the accuracy of the installation position and size. In the field of scientific research, scientists often need to measure the size of tiny objects.

Mobile Manufacturing

Mold Manufacturing

Scientific Research

Machinery Manufacturing

| Model | SISCO-DHG-DY150 | SISCO-DHG-DY200 | SISCO-DHG-DY300 |

| Graduation Value | 0.02mm | ||

| Accuracy | ±0.03mm | ±0.03mm | ±0.04mm |

| With Fine Adjustment Device | √ | ||

| Dimensions | 40cm×28cm×15cm | ||

| Weight | 4kg | ||

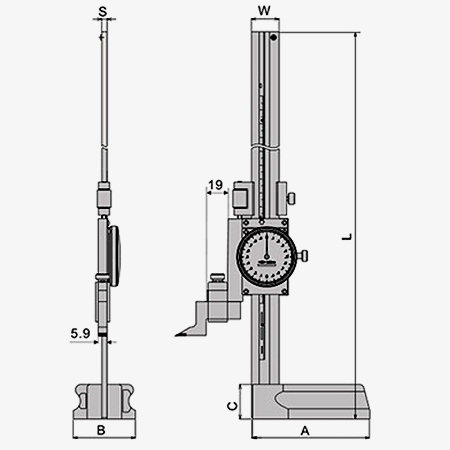

Structure Diagram

Packaging List

Q1: What is a vernier height gauge?

A1: The vernier height gauge is used to measure vertical dimension from the reference ground. Vernier Height Gauge consists of a graduated scale or bar held in a vertical position by a finely ground fixed base.

Q2: What is the advantage of the vernier height gauge?

A2: Relatively simple to operate, their main advantage over other height gauges is the range of sizes they come in, meaning they can be used to measure a wide range of workpieces accurately. Typically, two scales are shown on the beam of the height gauge.

Q3: What is the vernier height gauge used for?

A3: Vernier height gauges are used in metrology and metalworking to detect or measure vertical distances. The height gauges are often used to measure a granite surface or scribe part features from a datum plane. To detect the measured feature, a scriber, test indication, touch probe, or CMM-style probe is often utilized.

Tips: What Factors Affect The Measurement Results of The Height Gauge?

The height gauge is a precision measuring tool that is widely used in various industries and scenarios such as mechanical processing and mold manufacturing. Its measurement accuracy is also affected by many factors. The first is the state of the reference table. The shape and position errors of the reference table will also have a more direct impact on the measurement results. Secondly, the technical level of the operator is the most important factor affecting the accuracy of the measurement results, because if the operator is unskilled and does not have the necessary professional knowledge and skills, it will lead to irregular operations and inaccurate data recording. In addition, if the surface of the measured object is uneven or uneven, such as curved surfaces or irregularly shaped objects, measurement errors may occur. In order to ensure the accuracy of the measurement results, the measuring tool should be calibrated as regularly as possible and the measurement should be carried out under standard environmental conditions. Use the measuring tool correctly during the measurement process and follow the operating instructions. Keep the measuring tool clean and well-maintained after use.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.