The Coriolis flowmeter is a high-precision, direct mass flow measurement instrument equipped with a high-definition backlit digital display screen that directly and quickly reads real-time flow, with a detection accuracy of up to 0.2%.

Stable Measurement

- The large high-definition LCD screen can display instantaneous flow, cumulative flow, density, and temperature.

- Without moving parts, it can remain stable in long-term operation and is suitable for repetitive work.

- The test range is wide, and it can measure various liquids, slurries containing solids, liquids containing trace gases, and medium and high pressure gases with sufficient density.

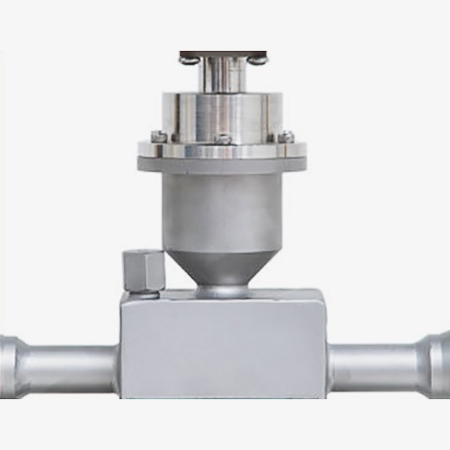

Quality Assurance

- Coriolis meter has a thickened 304 stainless steel professional protective shell, which fully protects the measuring tube and drive detection device, and is sandblasted to prevent fingerprints, and the quality details are visible.

- The internal high-temperature brazing process can effectively reduce stress and make the measurement process more stable.

- The flange is made of 316 stainless steel and the specifications are customized to meet different applications.

Application

In industrial production, a gas mass flowmeter can be used as a process automation control system detection instrument, can also be used to measure the number of materials in the total table; in energy, primary energy, secondary energy, energy-carrying masses, such as energy measurement, gas mass flowmeter is an indispensable tool in the process of energy management and economic accounting instrument. In environmental protection, gas mass flowmeter can be used for quantitative control of wastewater waste gas; in biotechnology, can be used for blood, urine, etc. detection.

| Model | SISCO-FLOW-VAFM | |||||

| DN(mm) | Flow Range(kg/h) | Zero Stablity, kg/h | Rate Pressure(MPa) | GW(kg) | ||

| 0.20% | 0.15% | 0% | ||||

| 3 | 0~96~120 | 0.018 | 0.012 | 0.012 | 40 | 19 |

| 6 | 0~540~660 | 0.099 | 0.066 | 0.066 | 20 | 22 |

| 8 | 0~960~1200 | 0.18 | 0.12 | 0.12 | 20 | 23 |

| 10 | 0~1500~1800 | 0.27 | 0.18 | 0.18 | 20 | 24 |

| 15 | 0~3000~4200 | 0.63 | 0.42 | 0.42 | 20 | 25 |

| 20 | 0~6000~7800 | 1.17 | 0.78 | 0.78 | 16 | 34 |

| 25 | 0~10200~13500 | 2.025 | 1.35 | 1.35 | 16 | 35 |

| 32 | 0~18000~2400 | 3.6 | 2.4 | 2.4 | 16 | 45 |

| 40 | 0~30000~36000 | 5.4 | 3.6 | 3.6 | 12 | 55 |

| 50 | 0~48000~60000 | 9 | 6 | 6 | 12 | 60 |

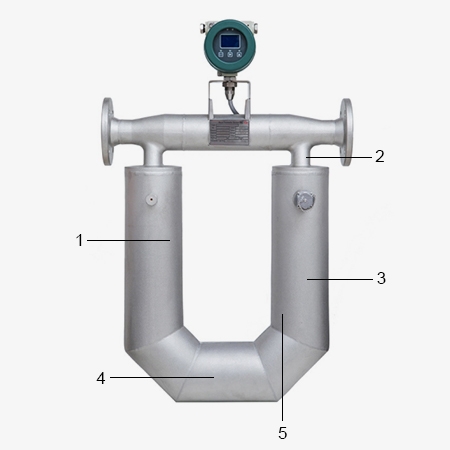

Structural Diagram

- Housing

- Support Structure

- Measuring Tube

- Drive Device

- Signal Detector

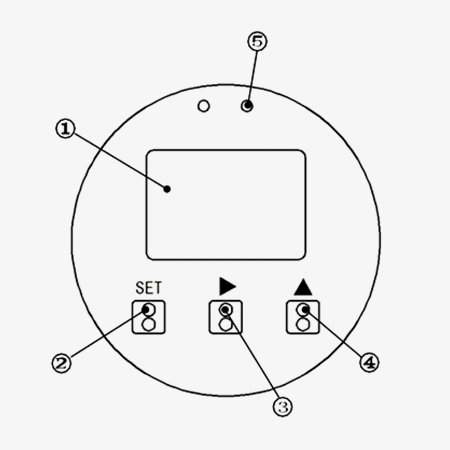

- Measurement Window

- [SET] Setting Key

- [>] Shift Key

- [Λ ]Add Key

- Status Light

Q1: Can a gas mass flow meter have perfect accuracy?

A1: In an ideal world, the flow readings from your process meter would be exactly correct, without any type of deviation. Unfortunately, this is not the case, and the errors inherent in measurement must always be identified, accounted for, and minimized as much as possible.

Q2: Does a gas mass flow meter need to be calibrated?

A2: During the production of a flow meter, several steps are required such as coil winding, lining processing, and electrode assembly. This series of operations can cause a certain amount of error and dispersion in the device, so a calibration process is required to correct the accuracy.

Q3: Do gas mass flow meters have temperature and pressure compensation?

A3: Our MF4000/5000/5700 series are all without temperature/pressure compensation. As long as the gas is under working pressure & temperature ranges, the accuracy will be as stated.

Tips: Advantages of U-Type Mass Flow Meter

As a typical structure of a Coriolis mass flowmeter, a U-type mass flowmeter has significant advantages in specific application scenarios due to its unique geometric design and vibration characteristics. The U-shaped tube bending design reduces the occupied space, is suitable for small installation environments, and supports multi-directional installation. The curved tube shape reduces the impact of fluid flow noise on the sensor, and the signal is purer. There are no moving parts, the failure rate is low, and only regular calibration is required on a daily basis, which reduces long-term operation and maintenance costs.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.