An impact tester is a special device used to test the mechanical properties (such as toughness, brittleness, fracture resistance, etc.) of materials and products when subjected to instantaneous impact or collision. It can simulate the impact, vibration, or impact strength that may be encountered in various real environments, helping companies and research institutions to evaluate and improve the quality and reliability of products. The impact testing machine is widely used in materials science, automobile manufacturing, aerospace, construction engineering, and other fields. Charpy impact tester and Izod impact tester are both commonly used impact testers. In this article, SISCO Online Store will introduce these two types of impact testers in detail.

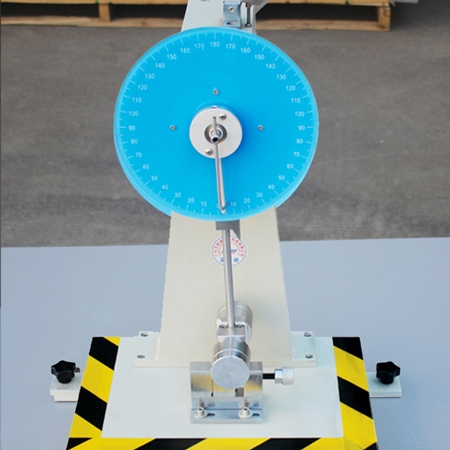

Charpy Impact Tester

The Charpy tester is a device used to test the impact resistance of metal materials under dynamic load. This tester is mainly used to evaluate the behavior of materials under high-speed deformation, especially the impact resistance under dynamic load, and to determine the notch sensitivity (toughness) of metal materials.

The working principle of the Charpy impact tester machine is based on the law of energy conversion and conservation. A specimen with a specified shape, size and notch type is placed on the specimen support of the impact tester to make it in a simply supported beam state. Then, a pendulum of a specified height is used to strike the specimen once. During the falling process, the potential energy of the pendulum is gradually converted into kinetic energy. When the pendulum strikes the specimen, the kinetic energy of the pendulum is transferred to the specimen, causing the specimen to deform and break. In this process, the energy of the pendulum is absorbed and consumed by the specimen. By measuring the energy change before and after the pendulum impact, the energy absorbed by the specimen under impact can be obtained. The pendulum impact tester can test the pre-lift angle of the pendulum and the reverse lift angle after breaking the specimen through an angular displacement sensor, thereby obtaining the pre-impact energy of the tester and the residual energy after breaking the specimen. The difference between the two is the energy absorbed by the breaking specimen, that is, the impact absorption work of the specimen.

Charpy impact test equipment usually adopts a single-column structure, a simply supported beam support, and a cantilever pendulum. This design makes the equipment more stable and reliable. The pendulum hammer is U-shaped, which helps to improve the accuracy and efficiency of the impact test. The impact tool is fixed by screws for easy replacement. Most of the test machines are semi-automatic, including lifting, hanging, impacting, and releasing operations are all electrically controlled, and the operation is simple. It can automatically lift the pendulum using the residual energy after breaking the specimen to prepare for the next test, which improves the efficiency of continuous testing.

Application Scenarios

In material performance testing, the impact toughness of metal materials can be tested, their resistance under impact loads can be evaluated, and whether the quality and performance of the materials meet the standards and requirements can be determined. It can also be used to determine the impact resistance of non-metallic materials such as plastics, rubber, and ceramics.

In the automotive, aerospace, electronics, and other manufacturing industries, it is used to detect the impact resistance of parts and products to ensure that they can withstand possible impact loads in actual use and ensure product quality and safety. It can also be used in the construction industry to test the impact performance of building materials and structures, and in the packaging industry to evaluate the impact resistance of packaging materials and packaging designs.

In research and development, the Charpy test equipment can be used to study the impact behavior and mechanism of materials, develop new materials, and improve the performance of existing materials. In the product design process, impact tests can also be used to evaluate the impact resistance of different design schemes and optimize product structure and material selection.

Izod Impact Tester

Izod impact testing machine is a device used to test the impact toughness of non-metallic materials, especially plastics and composite materials. It uses a pendulum to impact the sample and measures the impact absorption work when the sample breaks, thereby evaluating the toughness of the material.

During the falling process, the potential energy of the pendulum is gradually converted into kinetic energy. When the pendulum impacts the sample, the kinetic energy of the pendulum is transferred to the sample, causing the sample to deform and break. In this process, the energy of the pendulum is absorbed and consumed by the sample. By measuring the energy change before and after the pendulum impact, the energy absorbed by the sample under the impact can be obtained. At the same time, under the impact load, the notch of the sample will produce stress concentration, causing the sample to first undergo plastic deformation and crack expansion at the notch, and finally break. By analyzing the fracture of the sample, we can understand the fracture mechanism and toughness characteristics of the material, such as the morphology of the fracture, the direction and path of crack expansion, etc., which provides a basis for material performance evaluation and quality control.

The structure of the Izod tester is relatively simple and stable. The main machine of the tester is a single-support column structure, a cantilever pendulum method, and a U-shaped pendulum hammer body, which is easy to operate and maintain, and can provide highly repeatable test results.

Application Scenarios

In the research and development of new materials, the Izod impact tester can be used to evaluate the impact resistance of materials, help researchers understand the behavior of materials under impact loads, thereby optimizing the formulation and structure of materials and improving the impact resistance of materials.

In the material production process, the Izod impact tester can be used to conduct quality inspections on raw materials and finished products to ensure that the impact resistance of materials meets relevant standards and requirements, and to ensure the quality and safety of products.

In the production and quality control of electronic and electrical products, the Izod impact tester can be used to test the impact resistance of components such as housings and connectors to ensure that these components can withstand certain impacts without damage during transportation and use.

In the production and quality control of medical devices and packaging materials, the Izod impact testing machine can be used to test the impact resistance of disposable instruments, cold chain packaging, etc., to ensure that these products can maintain their performance and integrity during transportation and use.

Through the above understanding of these two impact testers, we can know that the Charpy impact tester is suitable for the impact toughness test of metal materials. It adopts the simply supported beam impact test method. The two ends of the sample are placed on the support. The impact load is applied to the middle of the sample by the pendulum. The work absorbed when the sample breaks is measured to better evaluate the overall toughness of the material. The Izod impact tester is suitable for the impact strength test of non-metallic materials. It adopts the cantilever beam impact test method. One end of the sample is fixed, and the other end is impacted by the pendulum. The energy loss of the pendulum when the sample breaks is measured to better evaluate the sensitivity of the material notch. If you want to choose more models of impact testing machines, you can go to the SISCO online store to buy.