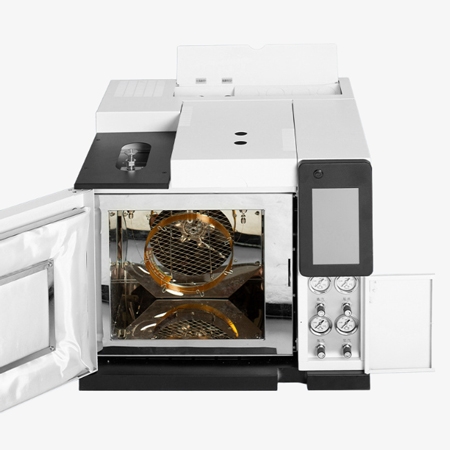

The SISCO 7-inch LCD screen gas chromatograph has precise measurement data, can be intelligently controlled, and is easy to maintain after use. The entire measurement process can be displayed in real-time. It is widely used in petroleum, chemical, pharmaceutical, food, environmental protection, disease control, scientific research institutions, and quality inspection departments.

Characteristics of a gas chromatograph

- Support computer anti-control: easy to operate, remote control.

- Seven-inch LCD screen: industrial color LCD screen design, more comprehensive display, and more reasonable interface operation.

The functions of 7-inch gas chromatograph

- Overtemperature protection: If any circuit exceeds the set temperature, the instrument will automatically power off and sound an alarm.

- Stable performance: capable of intelligent control and real-time display.

Applications

The SISCO 7-inch LCD screen gas chromatograph is an efficient analytical instrument widely used in various fields for the separation, qualitative, and quantitative analysis of components in complex mixtures. It is widely used in petroleum, chemical, pharmaceutical, food, environmental protection, disease control, scientific research institutions, and quality inspection departments.

Environment protection

Environment protection

Food

Food

Petrochemical industry

Petrochemical industry

Pharmacy

Pharmacy

| Model | SISCO-GC-YP |

| Name | Description |

| 7-inch LED screen gas chromatograph |

1.7-inch large screen LCD Chinese display, power-on self-test, wide range self-diagnosis, intelligent fuzzy control rear door opening system, over over-temperature power-off protection. 2. Configuration: Host+FID+SPL. |

| Standard sample | The object being measured |

| Capillary column | 30 m.0.32.0.5um |

| Workstation | Collect data N2000 |

| Air generator | Air purity: oil-free grade three |

| Output flow: 0- 3L/min | |

| Input pressure: 0-0.4MPa (adjustable) | |

| Rated power: 150W | |

| Hydrogen generator | Hydrogen purity: 99.99 |

| Output traffic: 0-300/min | |

| Input pressure: 0-0.4MPa | |

| Rated power: <150W | |

| Hydrogen gas cylinder + pressure reducing valve | Purity: 99.999% |

| Computer + printer | User provided |

Packing List

- 1 x 7-inch LED screen gas chromatograph

- 2 x Standard sample

- 1 x Capillary column

- 1 x Workstation

- 1 x Hydrogen gas cylinder

- 1 x Pressure reducing valve

Q1: What is a gas chromatograph?

A1: A Gas chromatograph is an instrument used for analyzing volatile compound mixtures, which can separate different components in a sample and perform qualitative and quantitative analysis. Widely used in fields such as environmental monitoring, food safety, petrochemicals, medicine and health.

Q2: How does a gas chromatograph work?

A2: Gas chromatography achieves component analysis by gasifying the sample and injecting it into a carrier gas stream, separating it through a chromatographic column, and then detecting the signals of each component with a detector. Common detectors include a hydrogen flame ionization detector (FID), a thermal conductivity detector (TCD), an electron capture detector (ECD), etc.

Q3: What are the common types of detectors in gas chromatographs?

A3: Gas chromatographs (GC) can be classified according to different standards, mainly based on their working principles, detector types, injection methods, and other aspects.

- FID (Hydrogen Flame Ionization Detector): High sensitivity, suitable for organic compounds.

- TCD (Thermal Conductivity Detector): Highly versatile and suitable for both organic and inorganic gases.

- ECD (Electron Capture Detector): Suitable for detecting halogen compounds, such as pesticides.

- FPD (flame photometric detector): used for sulfur-containing and phosphorus-containing compounds.

- MS (Mass Spectrometry Detector): can provide molecular structure information, with higher sensitivity and selectivity.

Tips: How is a gas chromatograph used?

1. Preparation work

- Turn on the gas source (usually nitrogen, hydrogen, air, etc., depending on the type of detector).

- Turn on the instrument power and preheat (the chromatographic column and detector require a certain temperature).

- Prepare samples (usually liquids or solutions, aspirated with a microsampler).

2. Set parameters

- Set column temperature, injection port temperature, and detector temperature.

- Set the flow rate of the carrier gas.

- Set the heating program (if using program heating).

3. Injection analysis

- Inject the sample into the injection port using a microsyringe.

- The sample vaporizes instantly and enters the chromatographic column for separation along with the carrier gas.

- Each component is separated and flowed out sequentially in the chromatographic column, and is recognized by the detector.

- The data is recorded by the chromatography workstation and displayed as a chromatogram.

4. Observe and analyze the results

- Each peak on the chromatogram represents a component.

- Retention time can be used for qualitative analysis (to determine what substance it is).

- Peak area or peak height can be used for quantitative analysis (to determine the content).

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.