A colorimeter is a highly sophisticated instrument that accurately captures subtle changes in the spectrum by performing an in-depth analysis of the light reflected or transmitted by an object. The key to this laboratory instrument is its ability to convert the complexity of light into numerical data to more comprehensively and objectively describe and understand the color characteristics of objects. This process involves the intersection of knowledge in multiple disciplines such as optics, spectroscopy and computer science, making colorimeters play an important role in scientific research, industrial production, art design and other fields.

In the operation of the colorimeter, it can not only analyze the color of light, but also determine parameters such as intensity and frequency of light, thereby comprehensively understanding the characteristics of light. This depth of analysis allows colorimeters to not only accurately measure the color of an object but also provide rich information about its optical properties. With this data, scientists, engineers, and designers can better understand and control the appearance characteristics of objects and achieve precise color management.

Working Principle

The working principle of a colorimeter is based on the principles of optics and spectroscopy. It numerically represents the color characteristics of an object through precise analysis of the light reflected or transmitted by the object. In the working of a colorimeter, the nature and wavelength of light are key factors. The following is a detailed explanation of the basic working principle of a colorimeter.

First, a colorimeter generates light from a light source, which can be white light or light of a specific wavelength. This light passes through a transparent transparency or directly hits the surface of the object being measured. In a reflection colorimeter, the light is reflected back, whereas in a transmission colorimeter, the light passes through the object and passes through one side of it.

Next, by using gratings, prisms, or filters, the colorimeter breaks the light into a spectrum of different wavelengths, or colors of light. This process is based on the physical phenomena of refraction, reflection and transmission of light. Each color spectrum has specific wavelengths, ranging from violet to red.

The colorimeter then measures the intensity of light at each wavelength in the spectrum by using a photosensitive element or sensor. These measurements are converted into numerical values, often expressed as chromaticity coordinates, which describe a color's position in color space. Common chromaticity coordinate systems include RGB, CMYK, and CIE XYZ, which provide standardized color representations to achieve color consistency between different devices and systems.

Ultimately, by processing and analyzing the measurement results, the colorimeter can accurately determine the color of the object being measured. These measurements can be used in a variety of applications including quality control, scientific research, art design, and more. In quality control, colorimeters help manufacturers ensure product color consistency and improve product quality levels. In scientific research, colorimeters are used to analyze the optical properties of substances and promote research in fields such as materials science and chemistry. In art design, designers can use colorimeters to accurately select and match colors to ensure that the design works to achieve the desired visual effect.

Applications

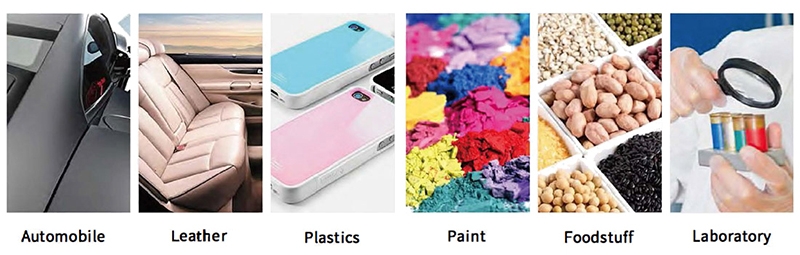

- Food industry: Colorimeters play a key role in food manufacturing by measuring the color of food to ensure product consistency and quality. The appearance and color of food directly affect consumer purchasing decisions, so colorimeters are used to monitor food freshness, ripeness and overall appearance. With precise measurement of food color, manufacturers can ensure products meet standards and provide an attractive appearance that meets market demands.

- Paint and paint industry: Color consistency of paints and paints is critical to the final appearance of the product. Colorimeters are widely used in this industry to ensure that the color of coatings meets design and specification requirements. By measuring color in real time, manufacturers can monitor the production process, prevent color discrepancies, and improve product quality and consistency.

- Textile industry: In textile manufacturing, colorimeters are used to detect the uniformity and color consistency of dyes to ensure that textiles meet the required color standards during production. This is essential to produce high-quality textiles and ensure consistency from batch to batch. Colorimeters help manufacturers control the dyeing process and improve production efficiency and product quality.

- Cosmetics manufacturing: Colorimeters are used in the cosmetics industry to measure the color of products, including lipsticks, eye shadows, etc. Ensuring that cosmetics colors match design requirements is critical to maintaining brand image and meeting consumer expectations. By using colorimeters, cosmetics manufacturers can achieve consistent product color and increase market competitiveness.

- Drug manufacturing: The color of a drug is an important component of its appearance and a key feature for patients and healthcare professionals to identify and differentiate between different drugs. Colorimeters are used in pharmaceutical manufacturing to ensure drug color consistency, thereby improving product quality and safety. By monitoring changes in drug product color, manufacturers can quickly detect potential quality issues.

- Plastics and rubber industry: Colorimeters play a key role in the manufacturing of plastic and rubber products, helping manufacturers ensure that product colors meet expected standards. This is particularly important in the production of plastic packaging, rubber products and other plastic parts. Through the use of colorimeters, manufacturers can avoid product color differences and improve product market acceptance.

- Research and development: In scientific research and laboratories, colorimeters are used to analyze color changes in substances, which is critical for studying chemical reactions, optical properties, or other physical properties. Researchers can measure color with a colorimeter and gain an in-depth understanding of the property changes of substances under different conditions, thus promoting the development of scientific research and new technologies.