The portable Shore hardness tester with a digital display, hardness value 90 C to 20 D, testing range 10~90 H, accuracy ≤ ± 1H, resolution 0.1H. The type DO shore durometer measures materials with DO rating hardness, such as moderately hard rubber, thermoplastic elastomers, and very dense textile windings.

Hardness value 90C~20D and measurement range 10~90H is available.

- sisco shore DO hardness tester has an integrated design, small size and simple structure, easy to use, and intuitive reading.

- Portable shore DO hardness durometer has a low battery alarm indication and average value calculation function.

Supports USB data transfer/Bluetooth data output

- The digital shore DO hardness tester has automatic shutdown and manual shutdown functions.

- Shore DO hardness durometer supports USB data transfer and can be connected to a PC. It also supports Bluetooth data output. These two items are optional, please contact us if you need them.

Applications

sisco Shore hardness testers are available in A, B, C, D, E, O, DO, and OO types to meet your needs for hardness measurement applications of different objects. Portable hardness testers are widely used in the hardness determination of rubber and plastics.

- Model: SISCO-AS-120DO

- Hardness Scale: Type DO

- Hardness Value: 90C ~ 20D

- Measurement Range: 10~90H

- Accuracy: ≤±1H

- Resolution: 0.1H

- Display Range: 0~100H

- Case High impact resistance: ABS

- Operating Temperature: 0~40℃

- Power Supply: 2x1.5V AAA Um-4 Battery

- Indenter: 0.79 Truncated (frustum) cone

- Dimension: 170x63x24 mm

- Weight: 310 g (Not including batteries)

Applicable Materials: Moderately hard rubber, thermoplastic elastomers, very dense textile windings

Accessories

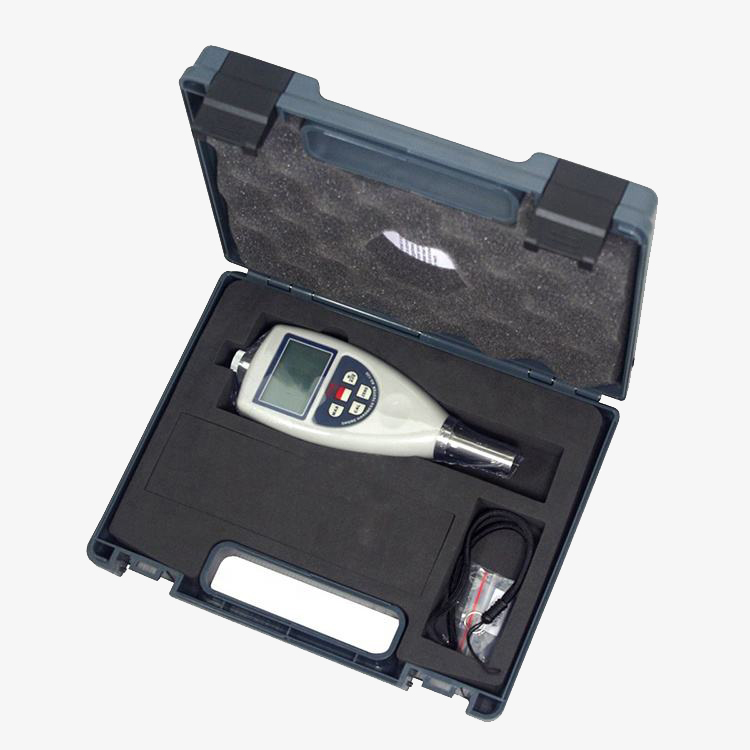

- Standard Accessories: Main unit, test block, carrying case, operation manual

- *Optional Accessories: USB data output, BlueTooth data output (If you need USB/Bluetooth output, please contact us)

Q1: What is a Shore hardness tester?

A1: A Shore hardness tester (Shore durometer) is widely used in the hardness determination of rubber and plastics. It has a simple structure, convenient use, small size and light body, and intuitive reading. Digital Shore A/B/C/ D/DO/E/F/O/OO hardness testers are available on sisco.com.

Q2: What are the 6 steps of sisco hardness tester measurement?

A2:

- The specimen should allow the measurement to be taken at least 12 mm from any edge. The specimen surface should be flat and parallel to allow the presser face to contact the specimen over an area that has a minimum radius of 6mm from the durometer probe. The specimen may be constructed with layered pieces to achieve the necessary thickness requirements, however, measurements taken on these specimens may not agree with those made on solid specimens, due to the surface faces between layers not being in complete contact.

- Depress and release the “Power key" to power the tester on.

- Depress the "MAX" key till the mark MAX shows on the display.

- Hold the durometer vertically with the point of the indenter at least 12 mm from any edge. Apply the presser foot to the specimen as rapidly as possible, without shock, keeping the foot parallel to the surface of the specimen. Apply just sufficient force to obtain firm contact between the presser foot and the specimen. Hold for 1 or 2 seconds, the maximum reading can be obtained automatically.

- To take the next measurement, just depress the "Zero key" and repeat 4. On the other hand, you can depress the "Max hold key" till the mark MAX disappears from the display. And then repeat steps 3 and 4.

- If other than a maximum reading is needed, no need to set the mark "MAX” showing on the display. In such cases, the reading on the display is an instant value. Just hold the durometer in place without motion and obtain the reading after the required time interval ( Normally less than 1 second)

Tips: How to take the average value of Shore hardness tester?

- To take the average value of many times of measurements, just depress and release the "N/AVE key" to make the symbol "N" showing on the display, followed by a digit between 1-9 with the prefix. Here the digit is the time of measurements used to calculate the average value. Every time depress and release the "N/AVE key", the digit will increase by 1. And the digit will become "1" while depressing the "N/AVE key" at "9".

- Adjust the digit to the number needed and depress the "MAX key" or "Zero key" to return to the measurement state or wait for several seconds till"0" on the display.

- Take measurements correctly. Be sure that every test should be 6 mm apart. Every time take a measurement, the reading and the times of measurements show on the display. When the times of measurements are equal to the number set, the unit first displays the reading of the last and then displays the average value of the last "N" measurements, followed by 2 beeps, with a symbol "AVE" indicating on the display.

- To take the next average value, just repeat 3.

- To release from average measurement, just depress the"N/AVE" till "N" disappears.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.