DRO digital readout 3 axis, input signal TTL, resolution 0.2um, 5um, um, um 20, or 50um, suitable for milling machine, drilling machine, grinding machine, lathe, contour projector, video measuring machine, position monitoring, coordinate measurement and other fields.

Quality panel keys

- Digital readout with high brightness digital tube, clear digital display.

- Durable touch key panel with key operation sound indication.

- Digital readout can be connected to a scale or encoder, which can meet the needs of various machine tools.

Compact appearance and lightweight

- RS-23 output function outputs the current scale display value to the computer.

- Strong anti-interference capability.

- 24-bit dedicated counting IC, counting speed up to 4m/s at 0.001mm resolution.

Application

The digital readout can be connected with a grating ruler or encoder, and is used in lathes, milling machines, grinding machines, boring machines, drilling machines, wire cutting, spark machines, etc.

| Model | SISCO-DR-WE68003 | ||||||||

| Axis number | 3 Axis | ||||||||

| Resolution | 0.05μm, 0.1μm, 0.2μm, 0.5μm, 1μm, 2μm, 5μm, 10μm, 20μm, 50μm | ||||||||

| Input Signal | TTL, Frequency < 2MHZ, Current > 1mA | ||||||||

| Input Voltage Range | 90 VAC-240V AC | ||||||||

| Power | Less than 15W | ||||||||

| Max Measuring Length | 900mm | ||||||||

| Frequency | 50 Hz - 60 Hz | ||||||||

| Anti Interference Capability | Over 2200V | ||||||||

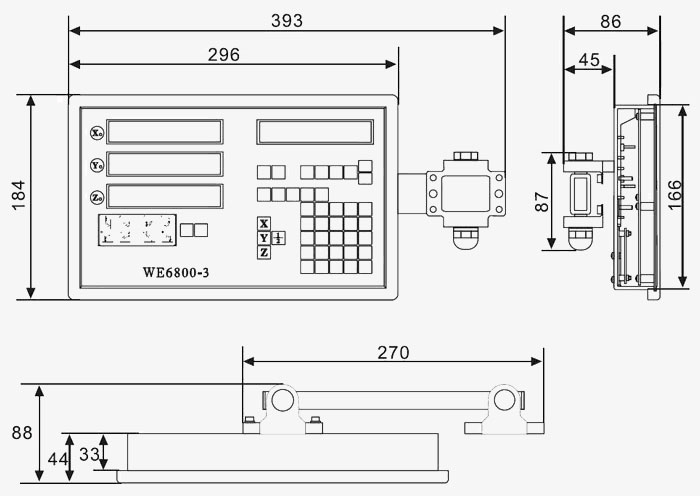

| Dimension | 296mm x 184mm x 44mm | ||||||||

Dimension (unit: mm)

A1: What does DRO stand for in CNC?

Q1: In machine shop terminology, a complete digital readout system (consisting of a computer, an axis position encoder, and a digital display) is represented by the acronym DRO.

A2: What is a digital readout system?

Q2: The Digital Readout (DRO) system is used to indicate the position of the cutting tool in relation to the workpiece. The position is detected by an encoder mounted on the shaft. They have a digital display and a keypad. DRO systems are used on milling and boring machines, lathes, and surface grinders.

A3: What are the advantages of digital readout?

Q3: Digital readout is powerful, fast frequency response can be directly on the raster digital display table for function calculation and convenient processing. Die-casting alloy shell, surface electric spraying treatment, dustproof and wear-resistant, good shielding. Raster digital display table professional design independent power supply, adapt to a wide range, high stability, strong anti-interference ability. The high-quality and durable key panel, is easy and convenient to replace.

Tips: What are the advantages of 3 axis digital readout?

- The digital display has the function of posting the machine and can be loaded and unloaded at any time. This is very common with other machine tools.

- No need for installation and adjustment procedures of other devices, easy to maintain.

- Versatile, the digital display can be used not only for milling, drilling, boring, turning and other conventional machining tasks, but also provides the ideal solution for many machine tools, measuring and testing equipment, and special machines, in fact, it is suitable for all manual machine tools.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.